Die casting is a crucial component of the manufacturing industry in Malaysia and is an integral part of manufacturing high-precision metal components that are used in a variety of industries. It involves pushing melting metal in a steel mold or a die under extreme pressure. This creates intricately designed components with outstanding quality finishes and exact measurements. In Malaysia Die casting industry has witnessed constant growth in recent decades, as a result of the increasing the demand of key industries like automobile electronics, electronic equipment, as well as home appliances. Since manufacturers are seeking the most efficient and economical manufacturing methods Die casting remains an effective solution, especially when consistency and speed are essential.

One of the major reasons for the need of die-casting for die casting in Malaysia is the automotive industry. Because of Malaysia being among the major manufacturing centres for automobiles that is why the need for light and long-lasting metal parts is essential. Die casting allows to make parts such as parts for engines, gearboxes as well as structural components that are durable and yet lightweight essential in modern automobile design, particularly due to the growing emphasis on the environment and fuel efficiency. Additionally, due to the increasing popularity of electric automobiles (EVs) and the growing demand for automotive business requires larger quantities of aluminum parts die-cast in order to decrease the weight of vehicles and improve efficiency in energy use. Malaysian die-casting companies can meet this increasing demand by providing quality parts that comply with strict requirements of the automotive industry.

Electronics are another important driver for Malaysia’s die casting industry. Since Malaysia is an important player in electronics production globally Die casting is a crucial process to create the complex components of metal used in gadgets including laptops, smartphones as well as home appliances. Die casting allows companies to make components that have tight tolerances that ensure the durability as well as performance of their end items. With electronic devices becoming smaller and faster-paced and more sophisticated, the need for die-cast parts that handle the requirements of miniatureization has increased. Malaysian die-casting companies are adapting by implementing modern techniques and technologies to make smaller and more intricate parts with greater efficiency.

Sustainability is now a primary aspect of the industry of die casting in Malaysia that is aligned to global trends towards more sustainable production practices. It is slowly shifting to more sustainable techniques, like using recycled materials as well as improving the energy efficiency in manufacturing. A lot of Malaysian die casting businesses have begun to adopt sustainable methods that are not just to lessen their carbon footprint, but to satisfy the increasing demands of international customers who prefer environmentally friendly production. Apart from recycling of materials improvements in the design of dies including improving the cooling of molds as well as reducing waste, help manufacturers improve both production and environmental sustainable practices. Sustainability is a key factor in making Malaysia’s die-casting industry as an innovative player on the international manufacturing scene.

Infrastructure development and the supply of skilled workers are also contributing to the expansion of the die casting industry in Malaysia. It is important to note that the Malaysian government has taken the lead in fostering the development of industry, providing incentives, tax break, as well as facilitating foreign investment in manufacturing. It has encouraged local firms to invest in modern technologies and die casting equipment which has improved the efficiency and efficacy of their processes. In addition, the focus of Malaysia on the technical and vocational training has led to a continuous number of skilled employees that are knowledgeable of the latest methods of manufacturing. The skilled workforce is essential to maintain the highest requirements for die casting, particularly when the field is moving towards greater precision and more intricate production techniques. For more information please visit here https://www.senadiecasting.com.my/

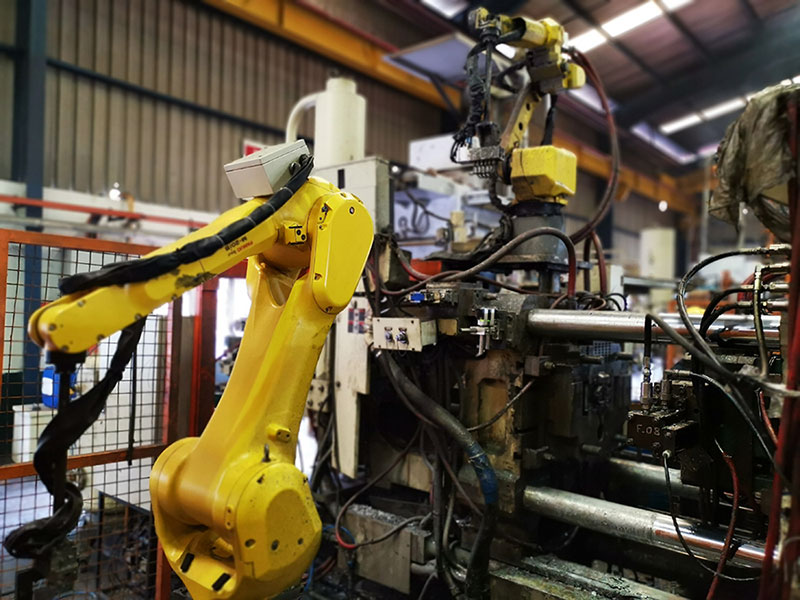

Innovation is at the heart of the industry of die casting in Malaysia and companies are always investigating new techniques to enhance productivity and the quality of their products. Automation and digitalization in the die casting techniques has helped companies to create more reliable quality and superior components, while also reducing the chance of human error as well as production time. Modern computers-aided design (CAD) and simulation software can also be used for optimizing mold designs to ensure an extremely high level of accuracy as well as reducing the chance of errors in the production process. The advancements in technology have allowed Malaysian companies that manufacture die casts to compete in an ever-changing global marketplace in which speed, quality as well as efficiency are the primary elements of the success of a company.

In the end, die casting in Malaysia is an essential component of the nation’s industry framework. It provides crucial components to a wide range of industries, such as automotive electronics, electronic and consumer products. Die casting’s capacity to create quality, high-end metal products at a reasonable cost is a compelling alternative for production in mass. In addition, with a focus on innovation, sustainability and the growth of skilled workers as well, the Malaysian die casting industry is well positioned to fulfill the increasing demand worldwide for die-cast parts. While industries are continuing to change and focus on efficiency and environmentally responsible practices, die casting is one of the key areas in Malaysia will become a more significant function in the coming years of manufacturing.